Do you have too much dust in your woodworking shop A dust collection system is a must if you are. A cyclone dust collector is one option that you might consider when comparing dust collection systems. This article will cover everything you need to know regarding cycle dust collectors in order to determine if they are worth your consideration.

Things To Consider Before Buying A Dust Collector

You should consider dust collection if you work in an area with poor ventilation. You should consider a dust collector. Exposed to dust can cause serious health problems, including pneumoconiosis (also known as dusty lungs).

There are several things you need to consider when considering purchasing a dust collector. First, think about what your dust control requirements are. Are you only producing dust by running machinery? Is it only generated under unstable conditions? How many hours per day does your machinery run if it is created by equipment?

Knowing how much dust you produce will help you choose the right type of system. Also, consider your budget. Do you have the budget to invest in a dust collector that will last years? Do you require something smaller? These questions can help you choose the dust collection system that best suits your needs.

Cyclone Dust Collector: A Brief Overview

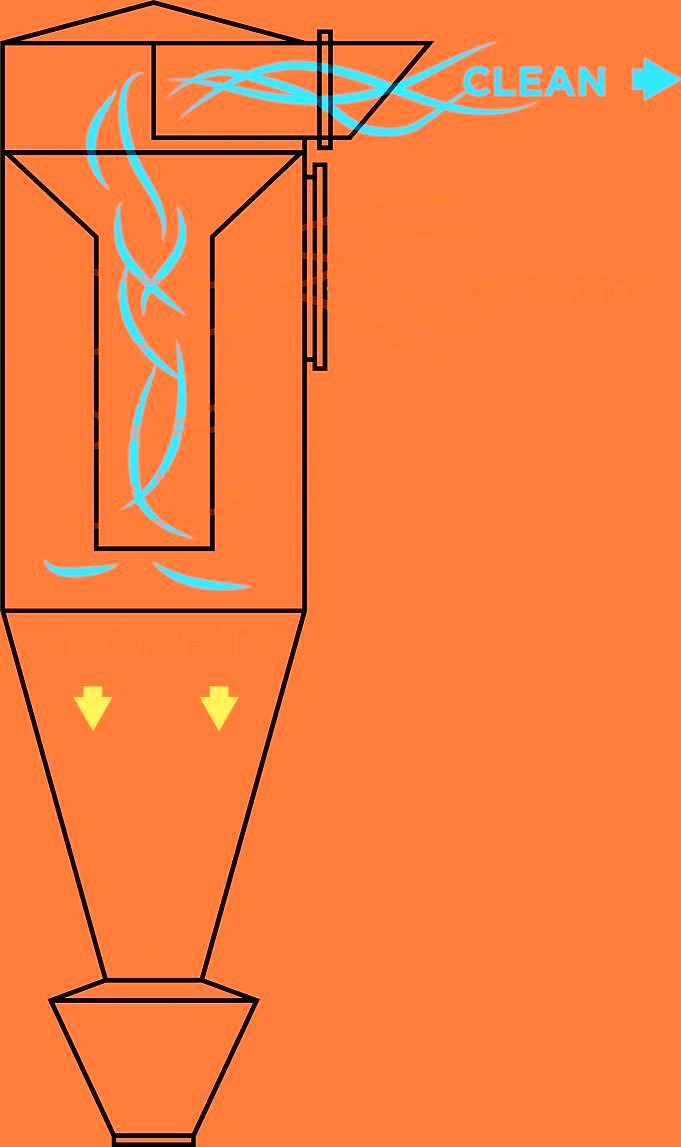

A cyclone dust collection is a product that captures the dust and debris you produce during machining operations. This includes planing and jointing. Manufacturers may refer to cyclone dust collectors with two collection points as two-stage dust collectors.

This dust collection system not only collects larger chips and other debris but also finer matter that might not be easily visible. A two-state dust collection system could make sure that your shop’s air quality is clean and healthy.

Cyclone dust collectors have some disadvantages. If the materials being processed are sticky or tacky, the units will not work. Dust collectors are not designed to collect particles less than 10 micrometers in size. These machines are capable of removing most dust particles from the air but they won’t be able to remove all.

What We Like

- Eliminate between 50 and 99 percent of dust particles from your air

- A cost-effective installation and maintenance process

- There are no moving parts

- It takes up very little space

What Could Be Better?

- Stickier materials will not work well.

- Do not collect dust less than 10 micrometers

Features And Benefits

There are a few features that make cyclone dust collectors stand out from other dust collection systems, as mentioned above.

Able To Handle Large Amounts Of Debris

Cyclone dust collection systems have the advantage of being able to handle large wood chips. Although single-stage dust collectors are capable of collecting smaller dust particles, your shop may still have wood chips and chunks. A cyclone dust collector is useful if your machinery tends to produce wood chips such as a lathe.

The cyclone dust collector draws air in and puts it in a cyclonic motion. Denser wood chips will fall to the bottom of the collector due to the cyclonic motion. The air continues spinning, and smaller dust particles are pushed through an impeller. They eventually settle in a filter canister. This filter filters the air and returns it to your shop.

Easier Clean Up

For a few reasons, cyclone dust collectors can help keep your shop clean. This is due to the fact that they can remove larger particles from your shop. These larger particles would need to be manually removed by a single-stage dust collection.

It would take hours to sweep and clean the floors in your woodworking shop. Two-stage dust collectors make it much easier to clean up.

The collection bag is another reason why cyclone dust collectors can be easier to clean up. A single-stage dust collector will produce a huge cloud of dust when the bag is removed from the machine.

This is not true if you use a cyclone dust collection. You won’t make a mess when you empty the container because the primary collection point contains only chips and debris.

Minimal Maintenance

Cyclone dust collectors are also easy to clean and maintain. Two-stage dust collection systems are more durable than single-stage units because they don’t have moving parts. You will only need a power source strong enough to support your machine.

The filter element is not as contaminated with particles as a single-stage dust collection. A single-stage dust collector would require all dust particles to pass through the filter. This can quickly cause damage to the screen.

This problem is not present in a two-stage dust collector. The filter is protected from the larger particles by the fact that they fall to the bottom of canisters naturally due to air pressure. This will increase the screen’s lifespan and make it more durable. If you have to replace your filters often, replacement filters can be quite expensive. This problem is unlikely to arise if you buy a 2-stage dust collector.

Convenient

Because they don’t take up too much space in your shop, cyclone dust collectors can also be a great option. A dual-stage dust collector is ideal for small shops. It can clean your air while also reducing your space.

Affordable

Dual-stage dust collectors are also very affordable. The smallest dust collectors are those you would use in a woodworking shop. Larger collectors can be found in larger factors and cost around. You should not have any trouble finding the right dust collector for you, while still staying within your budget.

Remember that two-stage collectors can be a significant upfront investment. Maintenance and replacement parts are not required for the machines. Once you have purchased the unit, your cost should drop significantly.

There Are Many Buying Options

Aside from size, there are other factors you should consider when purchasing a cyclone powder collector. One of the many benefits of cyclone collectors is their ability to be customized. You can actually build your own cyclone collector with a shop vacuum and a few other materials.

Your filter is one area you can upgrade. HEPA-grade filters are a good option, as they will not be exposed to wood chips or heavier particles. Although these filters are more costly, they can still process particles as small and as small as.3 microns.

The motor is another important aspect to consider when purchasing a cyclone dust collection system. The motor is the only moving component of the machine so make sure you get something that will last. Manufacturers offer a variety of motor options for dual-stage dust collectors. You should not have any difficulty finding the right motor for your machine when searching online.

Alternatives To Cyclone Dust Collectors

You may be hesitant to buy a cyclone dust collection unit or feel your woodworking projects don’t produce enough wood chips to warrant a two-stage dust collector.

Electrostatic precipitation is one of the best alternatives to two-stage dust collectors. These air cleaners use electrostatic forces to separate particulate matter. Dust particles are charged with electricity by an electric field that charges them.

The dust particles stick to the collection surface once they have electricity flowing through them. To remove dust particles, you can wash the collection surface.

These machines can be used in a variety of environments. These machines are extremely efficient and can handle corrosive substances. They also perform well at high temperatures. They may not be able to work with wood because it isn’t very good at conducting electricity. These units are also more expensive than dual-stage dust collectors.

A media filtration device is another option. These devices act as dust collectors. The filters collect dust as the air passes through them. These filters can be very efficient. They can be very efficient, but you will likely need to invest in product maintenance. This could quickly add up.

These filters are not suitable for use with high temperatures, corrosive chemicals, or products that have high temperatures. They are therefore not very versatile. These machines are not able to handle heavy dust loads. You will need to change the filter often if you are going to create a lot of dust. This can quickly become frustrating.

The third option is the cartridge dust collector, although it is less common. This machine uses a perforated, metal cartridge in the form of a cylindrical. The cylinder is lined with non-woven, pleated filtering media. Manufacturers seal the one-end of the cartridge while leaving one open. Clean exhaust is at the open end. These dust collectors can be used for reverse-air and pulse-jet cleaning.

Because they are so limited in their use, cartridge dust collectors don’t seem to be as popular. They can only be used with specific sized and shaped dust. The dust must be granular in shape and less than 50 microns. They are also unable to handle large volumes. They can only process five grains per square foot. This machine is useless for the average woodworker.

Last Thoughts

You should strongly consider installing a ventilation system if you work with wood. Dust can cause lung damage.

A dust mask might be sufficient to protect you if you do not woodwork often. If you work with heavy machinery in your woodworking shop, you might want something stronger.

A dust collection system is a must in these situations. There are two types of dust collection systems to choose from: a single-stage or a double-stage woodworking system. Single-stage devices filter polluted air through a filter. Double-stage devices use cyclonic, or compressed air, to compress heavier particles into a cylinder and then pass smaller particles through a filter.

Cyclone dust collectors are our preferred choice when it comes to keeping the air clean. This device collects heavy wood chips and does not require them to be passed through a filter. It also reduces the need for cleaning up and prolongs the product’s life. A single-stage device is best if you are producing wood chips often.

Dual-stage devices will also reduce maintenance. These machines do not have moving parts, even though they produce cyclonic air. The filter will last longer because it only contains very fine particles.

There are many dual-stage dust collection systems on the market. It should not be difficult to find the right one for you. You should consider your budget, your shop size, the type and number of machines you use, as well as the projects you are creating. Your lungs will be healthier if you do this.